- Concrete Mixer

-

- JS500 Concrete MixersJS750 Concrete MixersJS1000 Concrete MixersJS1500 Concrete MixersJS2000 Concrete MixersJZM500 Concrete MixerJZM750 Concrete MixerJZC350 Concrete MixerJZC500 Concrete MixerBN35 Concrete MixerBN90 Concrete MixerJZR350 Diesel Engine Concrete MixerJZR500 Diesel Engine Concrete MixerJDY(C) Series Concrete Mixer Machine

0086-371-8709 1886

ROOM 303, FLOOR 3, BUILDING NO. 1, NO. 51, HONGZHUAN ROAD, JINSHUI DISTRICT, ZHENGZHOU CITY, Henan Province.

Concrete mixers JZC350 Operation Manual

1.Application and Characteristic

This concrete mixer is a self-falling and movable concrete mixing machine, discharging with the double wimble rotating reversely. It could be used for mixing plastic and damp-dry rigid concrete. The mixing drum mixes the material by rotating positively, and discharges by rotating reversely. It is adaptable for architectural building site, civil engineer, and bridge project, small and medium concrete plant. You can dig a hole for fixed mix; it can make the hopper orifice level with the ground. By this way, feeding will be more convenient.

This machine is an advanced type of mixing machine. It is original in structure with a light weight and beautiful appearance. It can be operated and maintained easily and have a high productivity and good-quality mixing.

2.Main technological parameter

| Type | JZC350 |

| Discharge;Capacity | 350L |

| Charge;Capacity | 560L |

| Productivity | 10-15m³/h |

| Lifting;Motor | Y132S-4;;;5.5KW |

| Pump;motor | 0.55KW |

| Rotating;Speed | 14r/min |

| Max-size;of;Aggregate | 60mm |

| Hauling;Speed | 10-15Km/h |

| Weight; | 1950kg |

| Dimension | 2766x2140x3000mm |

3.Configuration

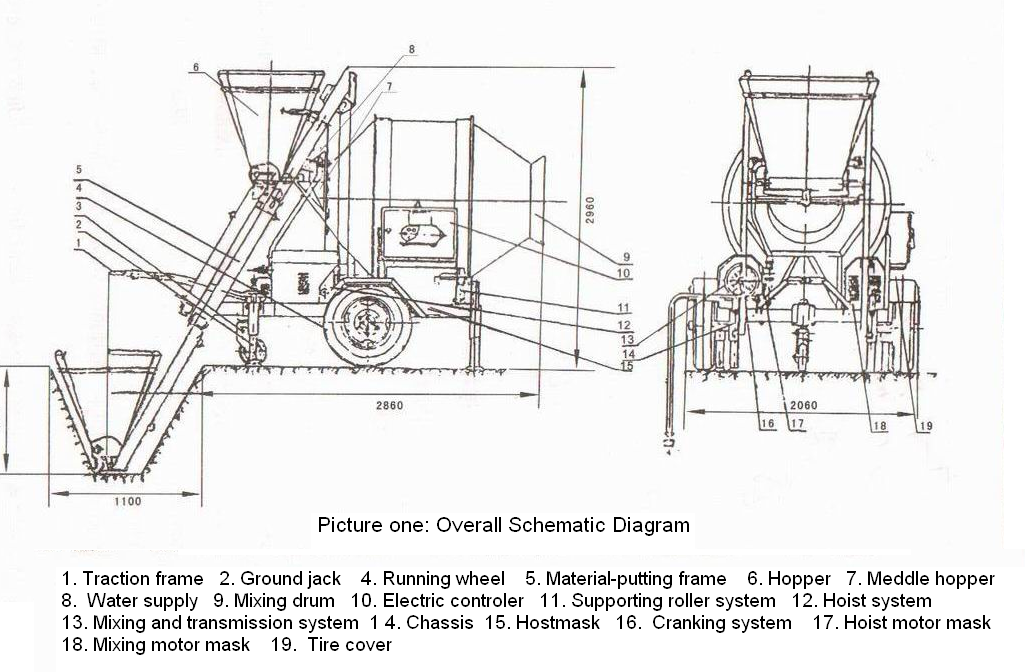

This concrete mixer consists of thirteen parts, such as mixing and feeding structure, water-supply system, chassis, wiring and etc. (As Picture One)

3.1Mixing Structure

Mixing structure consists of mixing drum, supporting roller, transmission system, and etc.

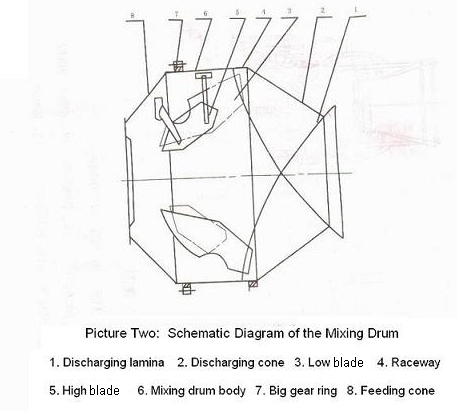

Mixing drum(As picture two)is the working part of the mixing machine. It has double wimbles, with two couples of high-low blades welded inside the mixing drum. The blades lay across and they both have an angle with the spindle of the mixing drum. When the mixing drum rotates, the blades will make the material upgrade and downfall, at the same time it makes the spindle comes and goes, so that the mixing movement is rather fierce, the concrete will be equal within about 35-45 seconds.

Also there weld a couple of discharging blades inside the discharging wimble. When the rotating direction of the mixing drum changes, the concrete will be pushed to the discharging blade from the low blade and then discharged from the mixing drum.

The mixing drum is sustained by four supporting rollers. The motor drives the ring gear through the reducer to make the mixing drum rotate, so it can work reliably even on a misty or rainy day.

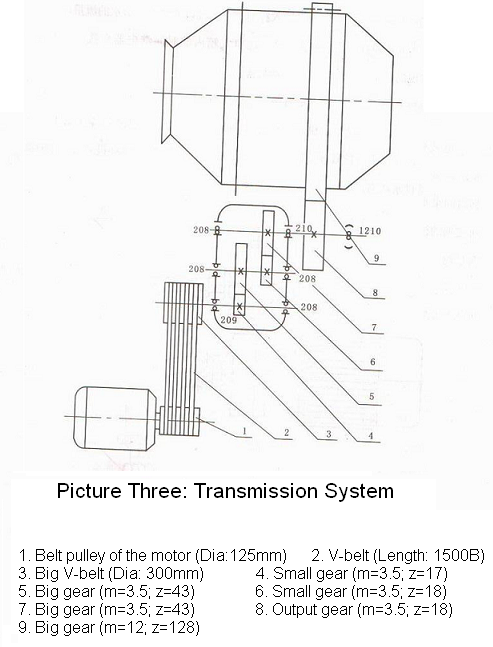

Transmission system (As picture three), the reducer box is a gearing reducer, the gear ratio is 6.04248, speed ratio of the triangle strap wheel is 2.3912, speed of the mixing ring gear is 7.1111 and the total gear ratio is 102.7467. The mixing drum rotates positively and reversely when the motor change its directions.

3.2 Concrete mixer Water supply

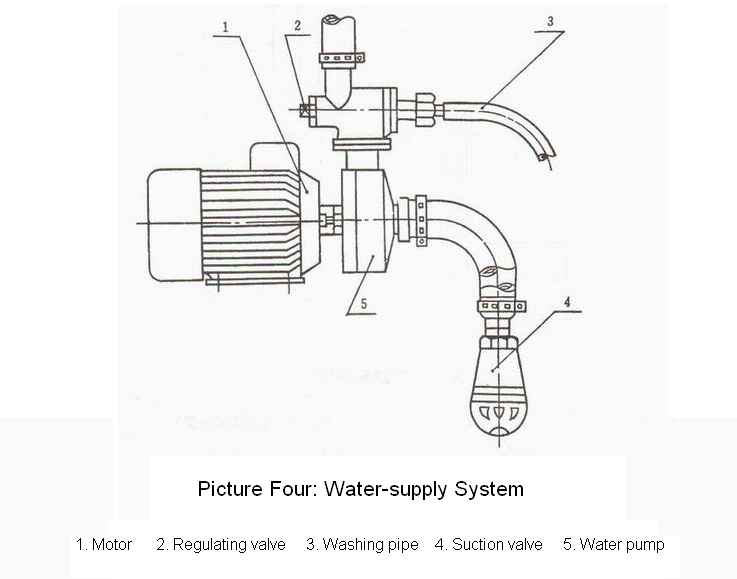

Water-supply system consists of motor, pump, adjusting valve and pipeline.

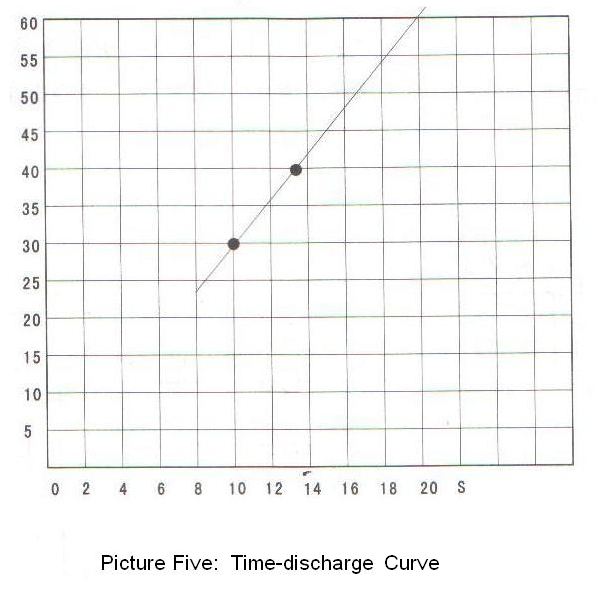

After the motor electrified, the pump will send the water into the mixing drum directly and regulate the water flow by adjusting valve (the flux has been adjusted suitably). The time relay in the electric box directly controls the motor of the water pump; it can regulate the water capacity of mixing. Consumers can decide the time according to the given time-flow diagram. There are two start-up buttons at the water supply site. For water supply, press the button on the left and then the water pump will start up. The water-supply electro circuit will automatically cut off when it reaches the stated time. After the revolving button on the right rotates, press the button on the left, then it could supply water continuously. You can wash the surface of the mixing machine by fastening the screw of the diffluent device and connecting the water pipe. And it will come back to the water-supply statement when you disconnect the screw.

3.3 Chassis

The chassis is welded by channel steel, with two tyres on the underside and towing bar in the front for towing. Also there installs a supporting wheel on the foreside of the chassis for placing or short-haul displacing. At each corner of the chassis, there is an adjustable strut. When the mixing machine works, maintain the strut fastened, so that it can enhance the stability of the machine. When towing, hang-up the supporting wheel, make the strut onto its top location and fix it with bolt, then install the lock spring in case of shaking.

3.4 Electric part

The principle of the electric control for this mixer refers to picture six. It makes the mixing drum mix, stop, rotate reversely and the pump supply water, stop and wash through six buttons.

4. New concrete mixers Check up and test run before use

Take an examination and test run for new mixer after reading this operation manual. The machine could be on stream only after the consumers are familiar with the operation method. The points of check-up and test run are as follows:

4.1 Settle the mixer

4.1.1 The perching ground must be even and stable. After placing the mixer, make the four brackets down, insert the bolts into the suitable hole and then install the safety lock spring. Following this, set the engine body onto the horizontal position or make the discharging hole lower. In order to enhance the stability of the mixer, please insure that the landing roadway is padded solidly and also for the tyre.

ZHENGZHOU BONA ENTERPRISE CO.,LTD.

Tel: 0086-371-8709-1886 E-mail: zzbona@zzbona.com

Concrete mixer Concrete batch plant Concrete mix plant Site Index | Product Index

Global sites

Global sites

(Live chat)

(Live chat)