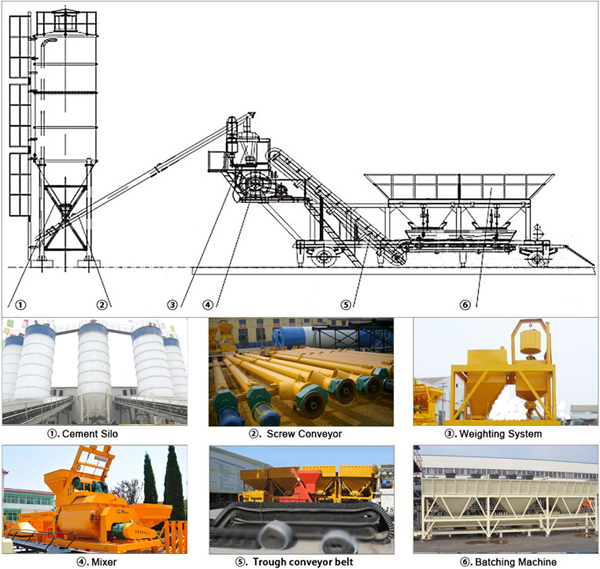

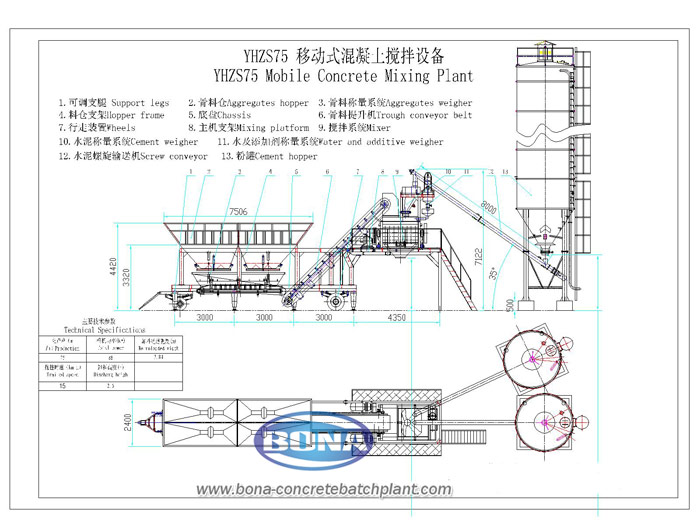

■ Descriptions of YHZS80 Mobile Concrete Batching Plant:

The modular design of without foundation and commissioning enables the modular concrete mixing plant convenient movement and quick installation. It only takes three days from installation to use. All necessary facilities such as: control room, laboratory and maintenance room are equipped. It is an ideal choice for engineering.

■ Features of low cost concrete batching plant:

1 "double composite spiral band" host using iron-chromium alloy wear-resistant materials, its shape and surface are with high shock resistance mechanical strength, good wear-resisting property, its center is with good toughness! Proper working life is 50,000 pots, a substantial increase in product life!

2. The whole plant uses automatic control systems, Siemens PLC, Schneider Electric components, computers and printing integration, simple operation, easy to debug.

3. Pneumatic system is with Taiwan Fusheng well-known air compressor, providing sufficient air supply for the entire concrete mixing plant.

4. Weighing system adopts international famous brands, weighing accuracy and sensitivity to ensure the quality of concrete.5. Using section structure, unit modulation, fast installation and debugging and moving is very convenient.

■ Technical Data of YHZS80 Mobile Concrete Batching Plant:

|

1. MIXING SYSTEM |

2. CEMENT SYSTEM |

|

3. AGGREGATE SYSTEM |

4. WEIGHING SYSTEM: |

|

5. WATER SYSTEM |

6. AIR SYSTEM |

|

7. ADDITIVE SYSTEM |

8. CONTROL SYSTEM: |

|

9.colorful computer |

|

Global sites

Global sites

(Live chat)

(Live chat)